It’s no secret, designing for manufacturing can be a difficult undertaking. Product engineers need to consider several variables that range from material and process selection to managing costs and deadlines. The team of application engineers at Protolabs understand this, and helps product developers with these challenges every day.

Our Ask an Engineer series highlights some of the most common questions we receive regarding manufacturing. And if you have questions please don’t hesitate to email us at ask@protolabs.com. There’s a good chance we’ll feature your question in our next post.

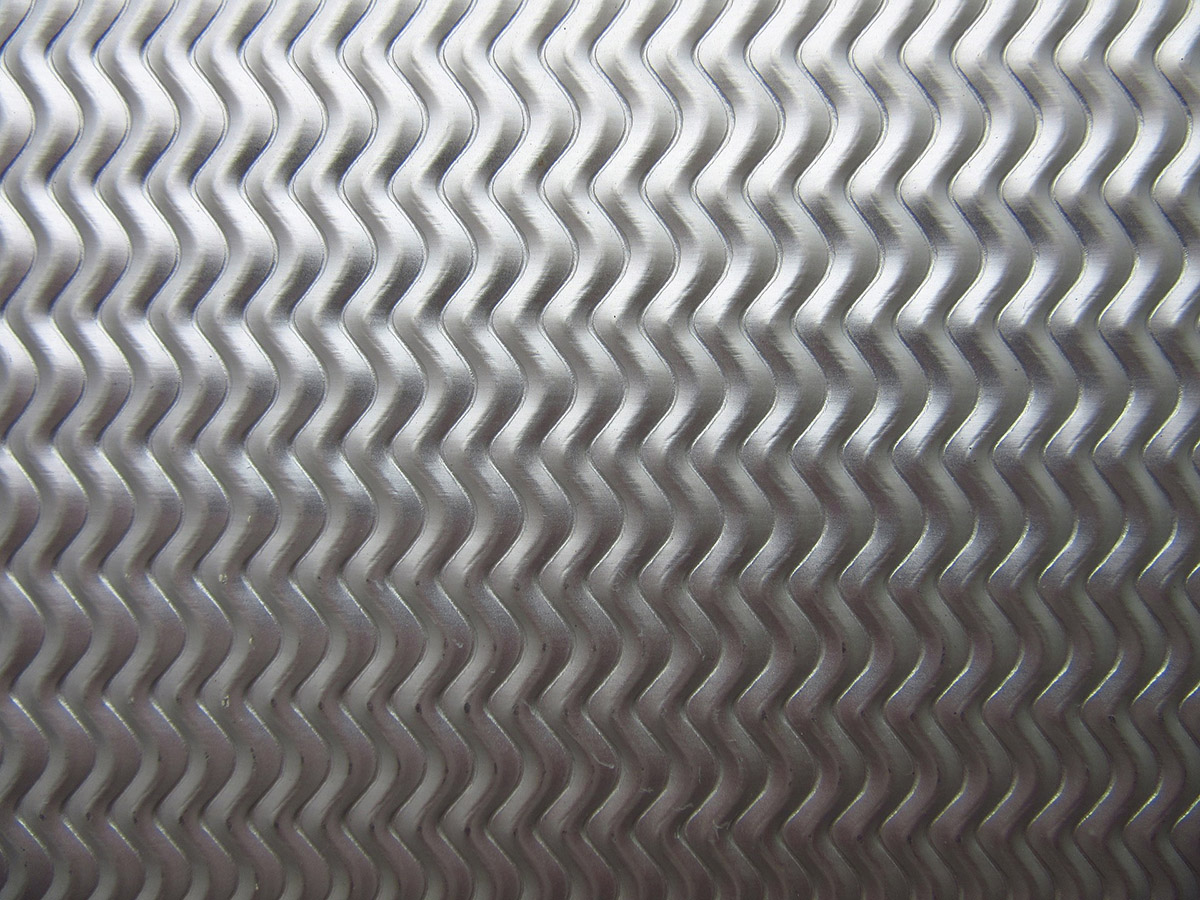

Sheet Metal Fabrication

Does the bend radius vary depending on material thickness?

It ultimately depends on the material. If we’re working on an aluminum part, we will often run a larger radius due to the properties of the grain structure. Aluminum is more likely to fracture along the grain direction when it’s being crammed into a smaller bottom. Steel is much more ductile compared to aluminum so we can effectively bend to whatever standard radius is required by the customer without quality concerns.